RUST PROTECTION, ANTI-CORROSION MARITIME TESTIMONIALS

Ship-2-Shore Wet Films are made for a wide number of industries - maritime, navy, coast guard, military, ships, trains, cars, mining heavy plant and equipment, refrigeration, agriculture, food processing, oil and gas terminals, tanks, sewerage and waste water. See the following testimonials proving high performance long lasting protection from moisture and corrosive contaminants and protection from rust.

Ship-2-Shore PLID and Industrial films are used and proven by Royal Canadian Navy (since 1995) and the Canadian Coast Guard Service (since 1996)

Nanaimo Marina Manager, Nanaimo, B.C. July 2015

"We had constant corrosion issues with electric connections and panels throughout the marina…nothing seemed to work…in 1998 we did all electrics throughout the marina with Ship-2-Shore…since, we've had absolutely no problems"....."In 2003 we did the same thing at our new marina…not a problem since…we always recommend Ship-2-Shore to our boaters"

Simon Bancroft, False Creek Tugboats Ltd., Vancouver, BC November 2004

Simon Bancroft, False Creek Tugboats, Vancouver, BC

"For the past eighteen months we have been

refurbishing out 1945 built steel tug Sea

Champ. One of the first jobs we performed

at the shipyard was to chip and de-scale the

steering flats. We then painted a coat of Ship

to Shore industrial onto the bare steel. After a

few weeks the steel in this damp unventilated

location appeared unchanged by moisture. No

Rust.

We were sufficiently encouraged to consider

replacing the badly rusted deck and frames

of the lazarette immediately forward of the

steering flats. We did this with unprimed

mild steel and when the job was done we

painted it with one coat of aluminium paint

and one coat of Ship to Shore. Whereas one

coat of aluminium paint on bare steel will

start bleeding rust within a couple of days, the

aluminium painted steels in the lazarette today

looks exactly as it did 6 months ago when the

job was done. The predominant colour is silver,

with a waxy pink tinge from the Ship to Shore.

The surfaces constantly drip moisture in this

unventilated part of the boat, yet there is no

indication of rust anywhere.

We were sufficiently encouraged to consider

replacing the badly rusted deck and frames

of the lazarette immediately forward of the

steering flats. We did this with unprimed

mild steel and when the job was done we

painted it with one coat of aluminium paint

and one coat of Ship to Shore. Whereas one

coat of aluminium paint on bare steel will

start bleeding rust within a couple of days, the

aluminium painted steels in the lazarette today

looks exactly as it did 6 months ago when the

job was done. The predominant colour is silver,

with a waxy pink tinge from the Ship to Shore.

The surfaces constantly drip moisture in this

unventilated part of the boat, yet there is no

indication of rust anywhere.

The ability of Ship to Shore and PLID to

neutralize the action of rust in difficult to

paint and inaccessible areas present new

possibilities for extending the life of steel

vessels.

We are still working through our five gallon pail

of Industrial, but we will need another case of

the spray cans of PLID. We find more and more

uses for this versatile product.

Addendum to this testimonial:

I spoke to Simon and he took a look in this

compartment: He reported everything looks

exactly like the day he did it in April 2004.

No rust anywhere and lots of Ship-2-Shore

present.

Vancouver Pile Driving North Vancouver

"We have been using Ship-2-Shore for

several years on the interior of our barges

and have found it to be an effective rust

inhibitor. VPDL would like to thank LCC for

introducing this product to our company".

"We have been using Ship-2-Shore for

several years on the interior of our barges

and have found it to be an effective rust

inhibitor. VPDL would like to thank LCC for

introducing this product to our company".

Neil Watson Inlet Navigation Ltd British Columbia Jan 2004

"We have been using Ship-2-Shore for about four or five years now, and are very pleased with the results. We use it on the tugs and barges in all the void spaces. We also use it on the trucks and forklifts that go on the barges, on all exposed areas. There is no rust period on any of this equipment. If you need any further information, give us a call or email us."

Paul Kruse Ocean Cement Sep 2000

We received this note from one of the largest

Tug and Barge companies on the BC coast

who have been using the Ship-2-Shore rust

inhibitors since 1998. I spoke to Paul and he

says they "are using the PLID in aerosol on

tugboat winch controls (bronze and brass) with

excellent success. No more seized valves.

Regarding preparation of steelwork before

application of Ship to Shore. We basically

needle gun all heavy scale/rust, coat the

affected areas with a Rust Converter, allow

for curing of Converter as per manufacturers

recommendations, overcoat the Converter

with a cheap (Grey) primer and then apply your

product (Ship To Shore).

We received this note from one of the largest

Tug and Barge companies on the BC coast

who have been using the Ship-2-Shore rust

inhibitors since 1998. I spoke to Paul and he

says they "are using the PLID in aerosol on

tugboat winch controls (bronze and brass) with

excellent success. No more seized valves.

Regarding preparation of steelwork before

application of Ship to Shore. We basically

needle gun all heavy scale/rust, coat the

affected areas with a Rust Converter, allow

for curing of Converter as per manufacturers

recommendations, overcoat the Converter

with a cheap (Grey) primer and then apply your

product (Ship To Shore).

We have performed this application in the shaft

tunnels, bilges (Engine Room & Aft Holds)

and chain lockers on 3 vessels up to this date,

"success rate is excellent".

Neil Watson, Inlet Navigation, Campbell River, BC.

"We have been using Ship-2-Shore for about four or five years now, and are very pleased with the results. We use it on the tugs and barges in all the void spaces... We also use it on the trucks and forklifts that go on the barges, on all exposed areas. There is no rust period on any of this equipment".

The Problem of Valves Oct 2002

We applied INDUSTRIAL to a couple of

966 loaders (including all the electrical

connections) used on salt barges, and an

excavator used to load potash.

Another use has surfaced: Ship-2-Shore

for valves and piping in manholes that get

flooded with water which contains salt and

other corrosive substances, running off from city

streets.

Here is an inexpensive and permanent cure

to the problem of valves and hydraulic hose

ends rusting when exposed to severe marine

environments.

Apply Ship-2-Shore INDUSTRIAL to the

valves. Wrap them with a clear plastic wrap

and secure with nylon ties. You can see the

valves, so monitoring is easy and the Ship-

2-Shore is enclosed, so it is permanent. You

will experience no corrosion and you can still

wash the area as often as necessary with no

detrimental effect. It costs about $3.00 per

valve and maybe 15 minutes of your time. This

would also work for flange connections on

large pipes on off-shore oil rigs.

Waste Water Barge Apr 2000

This old lube oil barge below is

now used to remove waste water (sewage) from

aircraft carriers.

Below is the hatch. (April 2000)

Preparation and Application

Getting started above, we soon found

that needle guns work much better than

prospector's picks.

The Ship-2-Shore appears white while applying

as the photo below shows, but it soon goes

clear.

After Use

After Use

This area had been submerged in waste water

for approximately four months, from August to

the end of December 2002, when they finally

got pumped out and hosed down. But now

there is no rusting here, the Ship-2-Shore

coating is 100% intact.

With the barge back in service, there was a

layer of slime remaining after pumping and

hosing out and as far as could be determined

the Ship-2-Shore coating was totally intact as

there was no sign of rusting. This photo

shows the layer of slime coating most of the

interior. I ran my finger through it in January

2003.

When this application was done the metal was

damp, there were oxides on the surface of the

metal. These rust marks are the result of

Ship-2-Shore displacing this moisture,

containing oxides, away from the metal.

The moisture has evaporated off leaving the

oxides behind. This is a good thing and a

clearly demonstrates Ship-2-Shore's ability to

displace moisture.

This photo shows that waste water sat in this compartment for over four months; things are really slimy but no rusting anywhere. Ship-2-Shore has formed a very protective barrier under the slime.

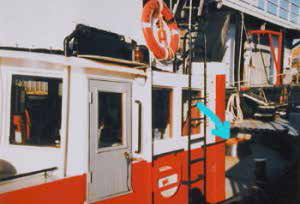

SeaSpan Tug Boat Lazarette 1994 to 2009

The lazarette, or steering compartment,

under the hatch (indicated by the blue arrow)

in the back of this SeaSpan tug is subjected

to stressed metal (dents), heat and humidity,

wet and cold. This is quite an aggressive

environment.

The lazarette, or steering compartment,

under the hatch (indicated by the blue arrow)

in the back of this SeaSpan tug is subjected

to stressed metal (dents), heat and humidity,

wet and cold. This is quite an aggressive

environment.

The lazarette had been painted in 1990.

When I entered in 1994 there was already a

very active rust stain coming from behind

this angle iron. Without preparation, although

the metal was wet, I painted Ship-2-Shore

stain off in two spots.

Two years later in 1996 I took the first picture of this series. Nothing crossed the top rub off, a slight stain is visible crossing the lower rub off proving this was very active at the time of INDUSTRIAL application.

1998 nothing has crossed the top rub off, the stain on the lower rub off has almost faded away, proving it is no longer being fed (the tear of a dying rust cell).

In October of 1999, five and a half years after application, there are no new rust stains. Behind the angle iron there seems to be as much Ship-2- Shore INDUSTRIAL remaining as when it was applied in 1994. This is performance! This is cheap maintenance so simple it's hard to believe.

This photo was taken in February 2004. Still nothing has crossed. This is proof that the rusting has been stopped 100% In 10 Years no rust appeared... not bad for one application of Ship-2-Shore. The application took 5 minutes, and no preparation or skill was required.

The photo above was taken August 2009. This is why repair yards don't want you using Ship-2-Shore.

No rusting after 15 years!

For further advice about the range of Thin Film, Industrial Thick Film, Thick Film, Float Coat or PLID Wrap, give us a call on (03) 9587 6022 or drop us a line!

EMAIL US